SunBin - Award-winning solar-powered interactive waste container

This post is about the SunBin, my graduation project for my Industrial Design Engineering degree in 2010. It was featured in the Dutch Jeugdjournaal (Kids News) and this will give you a quick introduction to the project:

In this post I will shortly explain what the SunBin is, the development process and achievements with this project.

Background

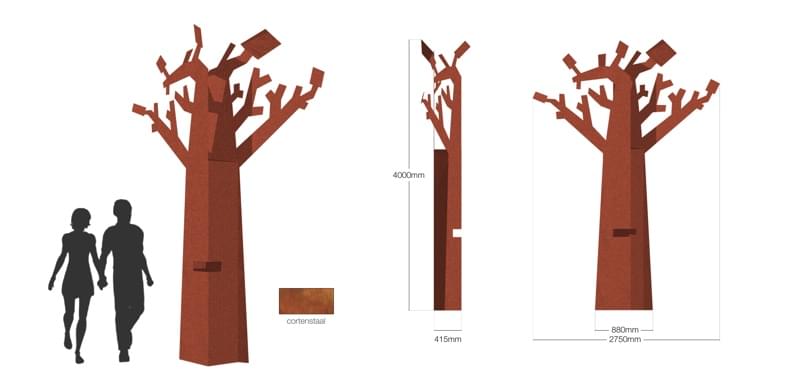

As mentioned above, the SunBin was my graduation project for my Industrial Design Engineering degree in 2010. It is a 4 meter high waste container made out of corten steel. The SunBin is the result of a collaboration between artist Lennaert Roos (PopFactory), 3 elementary schools, Royal Dutch Bammens (well-known manufacturer of waste systems in the Netherlands), 3 electrical engineering students and yours truly.

This project started with a simple assignment:

- Make an interactive waste container that plays a soundbite when people throw their rubbish in the bin. These soundbites will be created together with 3 elementary schools.

- The container has to be an autonomous system that can be placed in any park. The goal is to reduce littering by making recycling more fun.

- The container has to be suitable for series-production by Royal Dutch Bammens.

The development process

All in all this project took 6 months of fulltime work to complete. This included brainstorming sessions with the elementary schools, Bammens construction workers and a lot of sketching / 3D modelling. It is a rare opportunity to have a graduation project that is actually going to be manufactured - but also a lot of extra work. The slideshow below gives you an impression of the various stages in the development process from initial idea to reality.

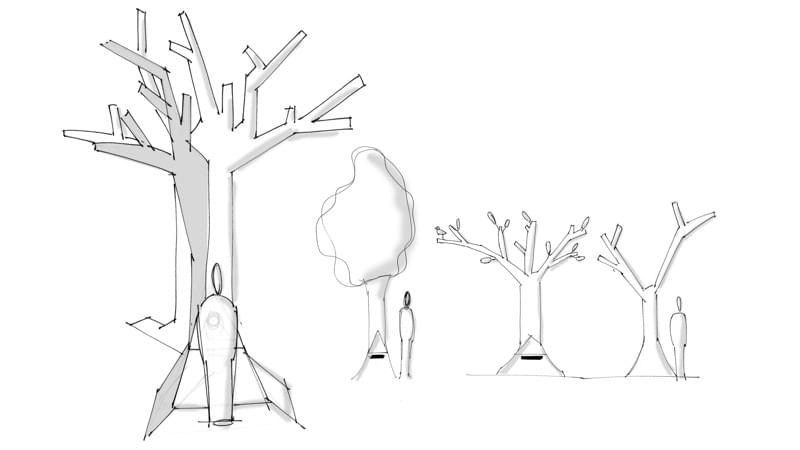

Initial sketches

A first conceptual mockup of the product

3D rendering of the Solidworks model

Another 3D rendering of the Solidworks model

The prototype being built in the workshop of Royal Dutch Bammens

A Royal Dutch Bammens employee working on the initial prototype

The reveal of the first prototype in park De Horst in The Hague

A word on sustainability

A lot of effort went into making the SunBin durable and sustainable. It has to withstand outdoor conditions for years. Apart from using a solar panel for the electronics, the choice for corten steel was a bit unusual for a company like Royal Dutch Bammens. In regular waste containers, a combination of zinc coating and powder coating is used to protect the container from rust. The downside to this, is the leakage of zinc into the soil. With the SunBin the usage of coatings would have been very difficult due to its large size (4 meters). That’s why I considered the possibility of using corten steel, which forms a protective layer of rust (patina) that eliminates the need for painting. This rusty appearance simultaneously added to the appearance and concept of a naturally ageing tree.

Milestones

- The SunBin made it to the Dutch national television (Jeugdjournaal, 05-11-2010). Check out the video at the start of this post.

- Graduated with a 10/10 grade

- Awarded 2nd place at the H/Link Thesis Awards.

- SunBin project wins HRP Retail Award 2014

- Press: “Unieke afvalbak in park De Horst” - Municipality of The Hague, 29-10-2010

- Press: “Papier Hier” - Telegraaf, 03-11-2010

- Press: “Unieke afvalbak in strijd tegen rommel” - Municipality of The Hague, 03-11-2010

- Press: “Ik vind een afvalbak best sexy, ja” - H/Link, 09-05-2011

- Press: “Uitreiking H/Link-afstudeerprijs.” - H/Link, 25-04-2012

How I was involved

- Ideation

- Concept development

- Product development

- Design engineering

- 3D CAD modeling

- Technical drawings / documentation

- Prototyping

Quick note: what happened after my internship

As of today, PopFactory is still actively promoting and selling the SunBin concept in various shapes and forms. Please note that I’m not claiming any involvement with the other versions that have been developed up to today. Also I’m not claiming any involvement with the SunBin marketing efforts of PopFactory. After my graduation project, several of “my” SunBins have been placed in parks in the Netherlands - of which I’m very proud.

More information

Sources

- Image courtesy: sketches, 3D models and workshop photos by myself, park photos by Joris Helming Fotografie, 2010

- Video courtesy: Het Jeugdjournaal, 05-11-2010